- Home Page

-

- Production Potential

Explore the Interactive CRIST Shipyard Model

To learn more about an object, hover over it.

-

Storage Yard

-

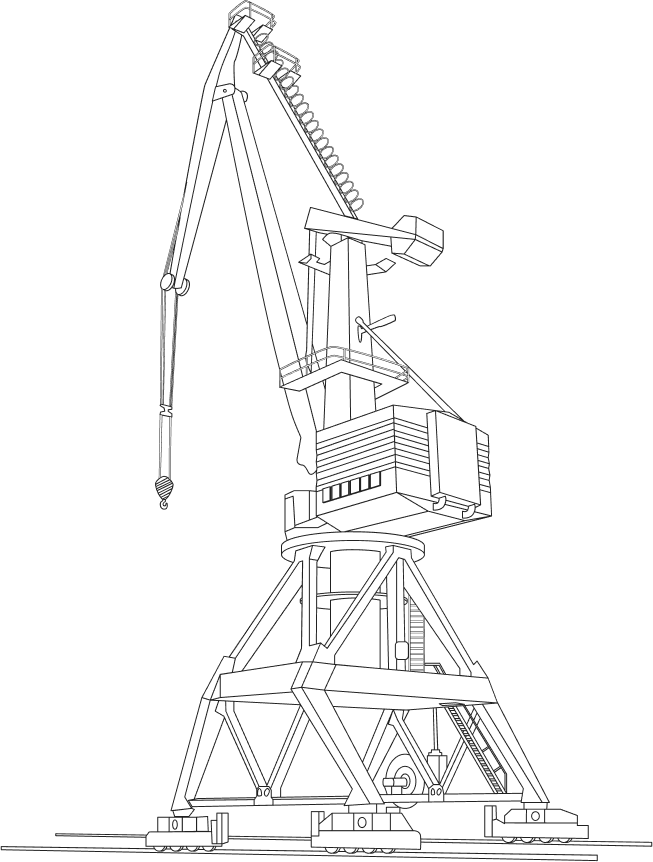

Gantry crane.

Q = 1000 t

Span: 153 m

Height: 106 m -

Prefab G-503 - 8 941,2 m²

-

Production Hall G-502 - 13 617 m²

-

Prefab G-06 - 8 604 m²

-

Two paint shops each with dimensions:

120 m x 13,5m -

Board Office

-

Production Hall G-08 - 13 036 m²

-

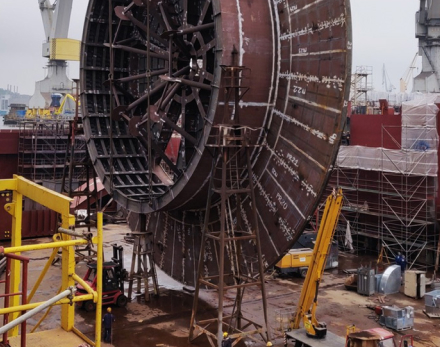

Dry dock 380m x 70m

(The dry dock can be subdivided into three distinct chambers, each measuring 123 m, 93.5 m, and 156.4 m in length) -

Main gate

Show directions -

Assembly Yard

We Have Great Capabilities

Shipyard Area

Annual Processed Steel

Capacity of Large-Diameter Pipe Production Line

Hydraulic Presses

Plate and Profile Cutting Machines

Annual Paint Consumption

Lifting Capacity of Each Kone Crane

Gantry Crane Height

Lincoln Electric Welding Machines

Gantry Crane Span

Dry Dock Length

Quality and Reliability

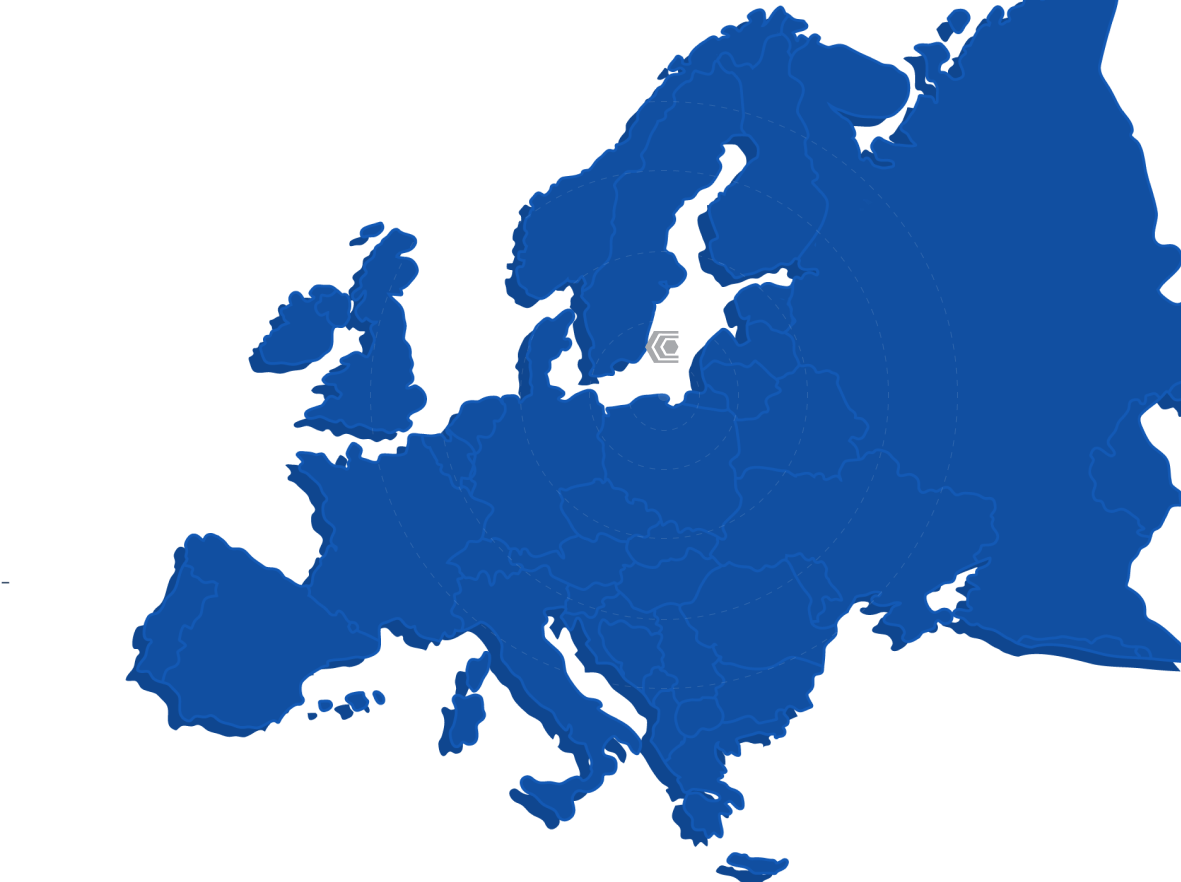

Crist has earned a reputation for its innovative, niche products and efficient supply chain management. We collaborate with clients from across Europe, including Poland, Germany, Norway, Denmark, Finland, Iceland, France, Belgium, the Netherlands, and Scotland. Our unwavering commitment is to provide services and products that not only fulfill but surpass our clients' expectations and requirements.

Reliability is a core focus of our projects. We ensure the highest quality, which is continually monitored and certified by leading global classification and technical organizations.

CRIST's Strength

Leveraging over three decades of expertise, we have honed a level of professionalism that we relentlessly refine, guided by the philosophy that complacency equates to regression. The bedrock of our strength lies in our exceptional engineering talent and top-tier technical competencies.

Our significant production resources include a Dry Dock measuring 379 meters in length, 70 meters in width, and 8 meters in depth, designated for the final assembly of floating units. We also have a gantry crane—one of the largest on the Baltic Sea coast—with a lifting capacity of 1,000 tons and a span of 153 meters. Additionally, our client-centric approach is a key strength, as we always prioritize our clients' needs. We strive not only to meet but to exceed their expectations by offering the latest technologies and customized solutions.

European Leader

Over

300Completed Projects

Employees and Engineers

Specialized

Production LinesEmploying the Most Advanced

TechnologiesSteel Processing Capacity up to

50 000Tons Annually

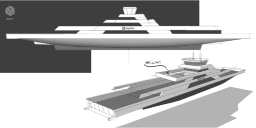

Project Potential

The CRIST Shipyard boasts an extensive portfolio of successful vessel projects, completed through collaborative partnerships.

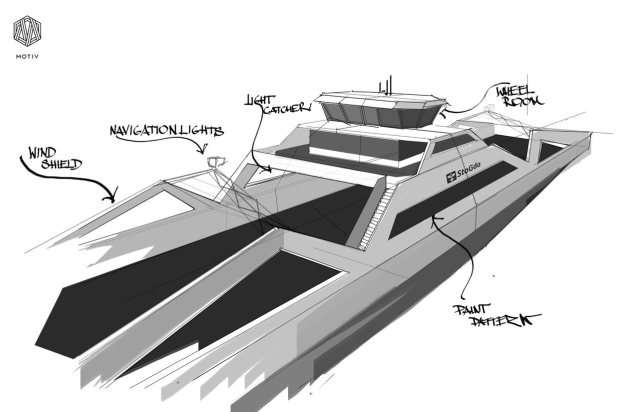

StoGda, a design office established in 1997 by former Gdańsk Shipyard Design Office employees, has celebrated its 25th anniversary in 2022. The company is actively engaged in both marine and land markets, designing ships, offshore structures, industrial installations, and gas compression stations.

To date, StoGda has completed contracts with partners on every continent, and its ships and structures can be found worldwide. StoGda places the highest value on quality, timeliness, innovation, and business integrity. The company emphasizes a positive office atmosphere and bases its partnerships on mutual trust.

StoGda offers comprehensive design services across all disciplines in the following areas:

- Shipbuilding: tankers, chemical carriers, ferries, passenger ships, car carriers, container ships, tugs, etc.

- Offshore Vessels and Structures: jack-up units for wind farm installation, CTVs, SOVs, supply vessels, barges, pontoons, etc.

- Offshore Structures: drilling and extraction platform structures

- Floating Technical Objects: caisson production docks, highway construction objects at sea, objects used for underwater tunnel construction

- Land-Based Structures: industrial structures and installations, gas compression stations

- Other: special and atypical projects

StoGda has participated in the design of four jack-up installation vessels for offshore wind farms, a field where only a few design offices worldwide operate. One of StoGda's projects, Vidar, received several awards, including in the Innovative Project category.

Furthermore, StoGda undertakes the design of modern and technologically advanced units, such as electric or hybrid-powered ferries and economical, eco-friendly chemical carriers.

StoGda has been collaborating with the CRIST shipyard continuously since 2007, successfully completing the following projects together:

- Jack-up Barge "Thor"

- Jack-up Vessel "Innovation"

- Jack-up Vessel "Vidar" (now "Vole au Vent")

- Floating Dock "Marco Polo"

- Jack-up Barge "Zourite"

- Battery Double-Ended Ferry "Elektra"

- Battery RoRo Passenger Ferry "Heljolfur"

- Battery Double-Ended Ferry "Altera"

- Battery Double-Ended Ferry "L-317"

- Mega-blocks for cruise passenger vessels for Chantiers de l’Atlantique

- Immersion Pontoons (IP)

- Multi-Purpose Pontoon (MPP)

More about StoGda: www.stogda.pl

More about StoGda

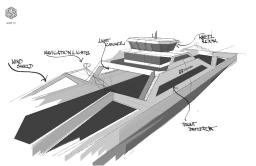

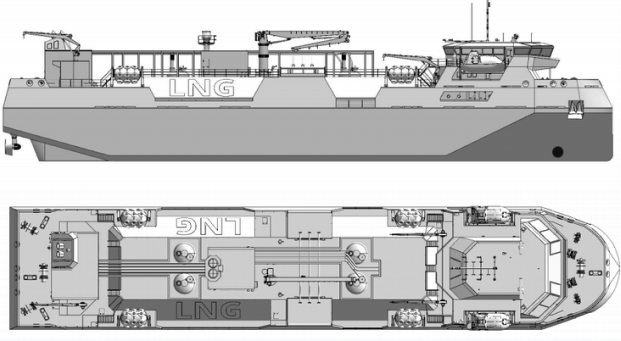

Seatech Engineering is a company founded in 2003, staffed by a team of qualified and experienced marine engineers and naval architects who specialize in projects for the shipbuilding industry. The company's primary office is located in Gdańsk, with an additional branch in Rumia. Since 2004, Seatech Engineering has been one of the leading design offices in the Pomeranian region, collaborating closely with the CRIST shipyard.

Seatech Engineering specializes in the design of medium-sized floating units for the maritime industry, including research vessels, offshore units, dredgers, passenger ships, and NATO warships. The company boasts extensive experience and a comprehensive portfolio of Small Scale LNG projects for the maritime sector. Furthermore, Seatech Engineering has intensified its activities in the areas of Crew Transfer Vessels (CTVs) and Service Operation Vessels (SOVs) due to the rapid development of the offshore wind energy industry.

Seatech Engineering not only carries out its own projects but also collaborates with shipyards during the production of new units and supports repair yards in ship modernization processes.

The scope of Seatech Engineering's activities includes:

- Concept and classification projects

- Preparing production documentation for shipyards

- Design of steel and aluminum hull structures

- Design of piping, ventilation, and air conditioning systems

- Construction supervision and management of sea trials

- Project management and oversight

- Design of non-standard buildings for shipyards, ports, and the onshore oil industry

Seatech Engineering's projects adhere to the highest standards for modern vessels while respecting maritime architectural and artistic traditions, as evidenced by their ISO 9001:2015 certification from Bureau Veritas. The design documentation is prepared using leading industry software tools, including Nupas-Cadmatic, Aveva, 3DExperience, NAPA, and Rhinoceros. The office's flexibility in adapting to other formats as per client requirements ensures seamless integration and optimal outcomes for every project.

More about SeatechCollaboration with the Maritime Advanced Research Centre (CTO S.A.)

The Maritime Advanced Research Centre (CTO) plays a vital role in supporting the CRIST shipyard's shipbuilding and other construction projects by providing a range of research services. CTO employs advanced technologies and research methods, including model testing, computational fluid dynamics (CFD) analysis, finite element method (FEM) analysis, and sea trial measurements. Furthermore, CRIST leverages the expertise of subcontractors who conduct product testing and certification for marine construction and equipment at CTO's facilities.