Women are an increasingly stronger representation in many manufacturing industries, even in those that have so far been associated with male domination. Eurostat data shows that every second employee in the IT industry is a woman. In automotive and chemical production this percentage is 35% respectively. and 36 percent. It is different only in the metal industry, where only 16 percent. employees are women. And how does it look in the shipbuilding industry? Getting better.

Agnieszka Jakubów deals with production logistics at the Crist shipyard.

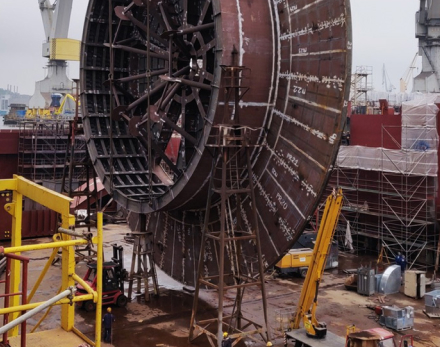

- My duties include, above all, planning and coordinating the transport of structures to the block assembly area, after its prefabrication is completed. Depending on the type of project, I plan the direction for a given structure, whether it is to go to the painting department, for equiping deparment or directly for assembly. I am also responsible for the logistic layout of the assembly area, so that we know when and where we will build our projects - says Agnieszka.

She came to the shipyard for an internship as a student of the Gdańsk University of Technology and has stayed till now.

- In the high school graduation class, I knew that I'm not a humanist and decided to try my luck at the Gdańsk University of Technology. I got to the Faculty of Ocean Engineering and Ship Technology in the so-called first recruitment. I was surprised because I thought it was unlikely after the humanities class. I was afraid that I could not cope with science, but after the first year I knew that I had made the right choice. At the beginning I didn't really believe that I could work in the production of ships, so I chose the specialization marketing and management in the maritime economy, which is thought would be a more feminine direction. However, despite everything, I was still drawn to the subject of production, which is why I wrote an engineering thesis on the quality control of welded joints on the example of a given structure, and I decided to study for a Master's degree in English: Ship technology and Offshore Engineering.

At first, Agnieszka became an assistant to the production master, then the junior production master, then again a technologist at the block assembly department, and today she is a production logistician. All this in just three years.

Emilia Kulczycka, in turn works in the Crist shipyard Project Managment Department.

- Our department is responsible for the direct implementation of the contract, i.e. the execution of the structure ordered by the shipowner, from the very beginning of the production processes to the final handover of the ship to the customer. I am currently working in a team responsible for projects for one of our main clients. I deal with, among other things, organization of materials for the construction of the hull and equipment, orders of ship equipment and fittings, launching documentation for the construction elements and explanation of current construction or execution errors. We also participate in the optimization of production processes related to the implementation of the project.

Ms. Emilia also graduated from the Faculty of Ocean Engineering and Ship Technology PG. However, she chose the Floating Object Technology specialization, and she graduated from the Master's Degree in Energy Systems Design and Modeling. Why the Polytechnic, why the shipyard?

- I'm not from the Tri-City, but I wanted to live here. I wanted to study achieve a technical degree and study science. And why the ships? Because I knew it would be a big challenge. I was very interested in subjects such as materials science, material strength and fluid mechanics, and many hours of practice. From machining to cutting steel with a torch and welding, all these classes ended with a practical exam. - says Emilia Kulczycka.

Edyta Kułaga-Dorsz is a welding engineer and also works at the Crist shipyard.

- Immediately after my master's degree in Mechanics and Machine Design at the Gdańsk University of Technology, I got an internship at the shipyard as a welding engineer. Although I specialized in welding at the Department of Machine Materials Technology and Welding, I additionally completed postgraduate studies for the International Welding Engineer IWE, which entitle me to supervise all kinds of work related to welding and soldering processes. I have been working for almost 9 years in my department. I am responsible for verification and management of permissions for welders and fitters, development of new welding technologies and technology instructions for implemented projects.

However, welding is also not strange for Edyta. At first she had to undergo a cutting and tacking course. She had to be able to do that, since she supervises the work of welders on a daily basis.

- I liked welding, because I knew I would find a job in this direction. We have bridges, we have ships, we have other steel structures that are and will be welded. And welders determine how to weld so that the welds meet the strength and quality requirements - says Edyta Kułaga-Dorsz.

Women at the Polytechnic

In all these three stories there is a common denominator. Namely Gdansk University of Technology. Even 8 years ago, women in technical studies in Poland accounted for only 30.7 percent of the students. Today, according to the Perspektywy Educational Foundation, this indicator increased to almost 37 percent. At many university faculties, strictly technical universities, however, they do not exceed a few percent. This is the case in the faculties of electronics, electrotechnics, mechanical and automation. Thanks to the "Women at the Polytechnic" campaign, which PG has been leading for several years, let's hope in a few years that these statistics will look even better for women.

Women in the shipyard are always present but mainly in accounting, human resources and of course in the halls as gantry cranes operators. Today, however, as you can see, they work more and more at the engineering positions, that until now where associated as typically male.

- At the beginning I thought that it would be difficult for me to be in the male dominated workplace. I have met with various comments many times, both nice and unfriendly. I was prepared for this. I knew why I was in the shipyard, so I was resistant to all critical voices - says Agnieszka Jakubów.

- I started working at the shipyard over 7 years ago. There were only men in the team. I found a great team that implemented me in shipbuilding processes. Of course, you can meet with various comments. This is a specific industry, you should not take everything personally. First of all, you need to be able to cooperate with many people and defend your own opinion. Throughout my work, I had the opportunity to participate in the leading shipyard projects. We have worked with clients from Germany, France, Finland, Iceland and Norway, where women also work in teams in various positions. I also took part in sea trials, where I could see many ship systems in operation. It was a great experience. - says Emilia Kulczycka.

- Often a woman in a male environment softens manners. In the company of women, men are more reserved - notes Edyta.

There is no place for fear in the shipyard

Interesting work, challenges .... It turns out that there are even more advantages of working in the shipyard.

- A big plus is that as a woman I don't have to think every day what to wear for work. I put on a shipyard uniform, a helmet, heavy shoes and I am ready - Agnieszka laughs.

And the family, partners? They are proud of their choice. Edyta's parents both also worked in the shipyard, and her husband also finished PG, where they also met. However, he chose another specialization. Emilia in turn met her husband in the shipyard. They worked in one team. This cooperation ended with ... a wedding and a unique photo session, of course at the shipyard.

- A walk in high heels over a large crane was an unforgettable experience - Emilia Kulczycka laughs.

However, one should not forget that this work is difficult and sometimes dangerous. - Work in a shipyard can be dangerous.

Women who choose this job can not be afraid of heights, because sometimes you have to climb the scaffolding, they also can not feel fear of entering narrow spaces, because there are many nooks on the ships. In difficult conditions you have to work both in winter and summer heat. You also have to reckon with the fact that sometimes people get dirty - says Emilia.

- Welding is very hard work, but there is one woman in our TIG welder team and she is doing great. Her wok requires high precision and skills - says Edyta Kułaga-Dorsz

- The most important thing is that this industry is future-oriented, there is work to be done. I would even say, that a lot of work - adds Agnieszka.

Source: Trojmiasto.pl

Author: Wioletta Kakowska-Mehring

Photo: Piotr Hukało